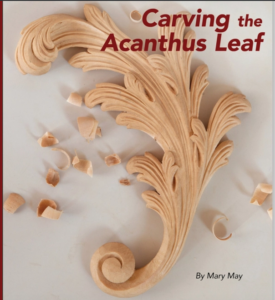

My new book, Carving the Acanthus Leaf, has been available for purchase since November from Lost Art Press (yay!). You can also view my Carving the Acanthus Leaf page on my website to learn more.

I recently made the casual comment “I just finished my first book”. My husband responded “you mean there’s more?” I think the “significant others” of authors deserve a lot of credit. How many late nights of clicking away on a keyboard, obsessive editing, and “I’ll only be a few more minutes” do they put up with? He’s a very patient man and I am so grateful.

I have been thinking about writing another book… I will admit. The process of writing my first book was an awesome experience in many ways. There were many times where I wondered whether I would ever reach the finish line. Then when I reached the end of the journey, I look back and think of all the other possibilities and directions I could wander. How many woodcarving books have not yet been written?

I think (or hope) I have discovered a way to teach that is easy for even the novice woodcarver to understand. And with that discovery, where shall I go next?

The following are standard learning styles:

- Visual (spatial):You prefer using pictures, images, and spatial understanding.

- Aural (auditory-musical): You prefer using sound and music.

- Verbal (linguistic): You prefer using words, both in speech and writing.

- Physical (kinesthetic): You prefer using your body, hands and sense of touch.

- Logical (mathematical): You prefer using logic, reasoning and systems.

- Social (interpersonal): You prefer to learn in groups or with other people.

- Solitary (intrapersonal): You prefer to work alone and use self-study.

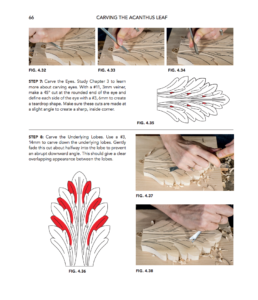

In writing this book, I have attempted to make the process of learning woodcarving available to every possible learning style (except for the “social” unless you get together with your neighbors to learn to carve acanthus leaves). In the printed book I have made instruction possible through detailed photos, drawings and written step-by-step instruction. I now also offer instructional videos that show the process of carving each leaf in action (Premium Members of my Online Woodcarving School receive a 15% discount on these video lessons). And if the written instruction along with the video lessons do not offer enough information, I have created resin study casts of my original carved leaves. Each casting of the leaf can be held in your hand to be studied and viewed to learn and understand the details of the physical carved leaf.

So, if you have ever had the desire to carve the classical acanthus leaf, what better time to learn than now?

And now I ask your help to please share the word about my book. Please speak with your local woodcarving club, your woodworking guild, museums, schools or any other group or organization that may be interested in learning about this classical design. Share on your blog, facebook, twitter, instagram, or whatever the latest and greatest social networking app is out there. It is greatly appreciated!